Kombucha is one of the oldest traditionally fermented beverages in the world. It is a sweetened tea, which achieves its characteristic aroma by symbiotically living yeasts and acetic acid bacteria. Due to its sweet-sour, aromatic character and not least because of the functional ingredients formed by the microorganisms, Kombucha enjoys increasing popularity.

Particularly in recent years the interest in Kombucha production has increased in the beverage industry as well as in the craft scene.

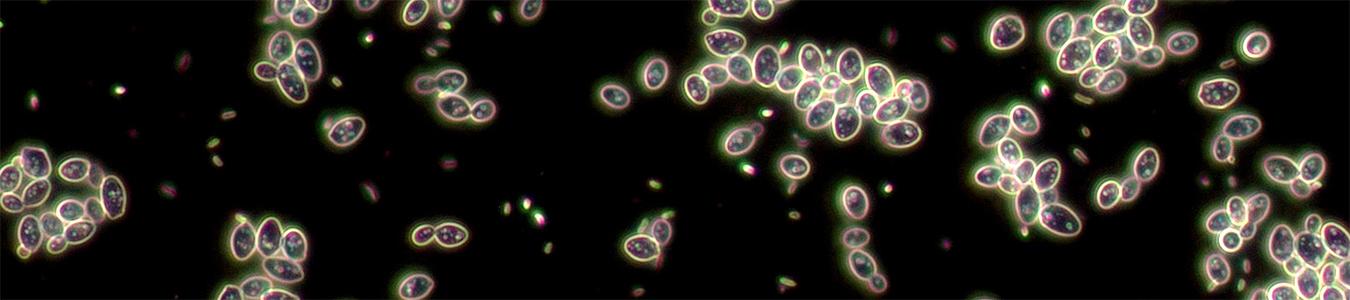

Taking a closer look at the course of a mixed fermentation, an enormous complexity manifests itself at the microbial level. The adaptation of the experience-based knowledge and a process transfer of Kombucha's traditional craftsmanship to a standardized and controlled industrial scale poses challenges for a producer. Therefore, appropriate quality assurance along the Kombucha production chain is essential to obtain a safe product that meets regulatory requirements.

Kombucha Process Development

- Provision of defined pure cultures for Kombucha fermentation

- Isolation and Identification of Kombucha cultures

- Cryopreservation and long-term storage (-70°C) of your strains

- Shelf-life and stability studies of your products

- Development of dried starter cultures

- Test fermentations at different scales using state-of-the-art process-accompanying analysis technology and support in the identification and evaluation of critical process steps

Kombucha Analyses

- Microbial analyses to evaluate your product and exclude pathogens and spoiling microorganisms

- Determination of ethanol, quantification of sugars and organic acids

- Nutritional analysis

- Marketability certificates

- Food safety (e.g. heavy metals and pesticides)

- Quantification of aroma compounds

Kombucha Packaging

- Selection of suitable packaging material depending on your product parameters

- Specification test for your glass + PET bottles, cans, closures, labels and cardboard

- Quality control for double seam, internal pressure resistance, and many more

Martin Senz